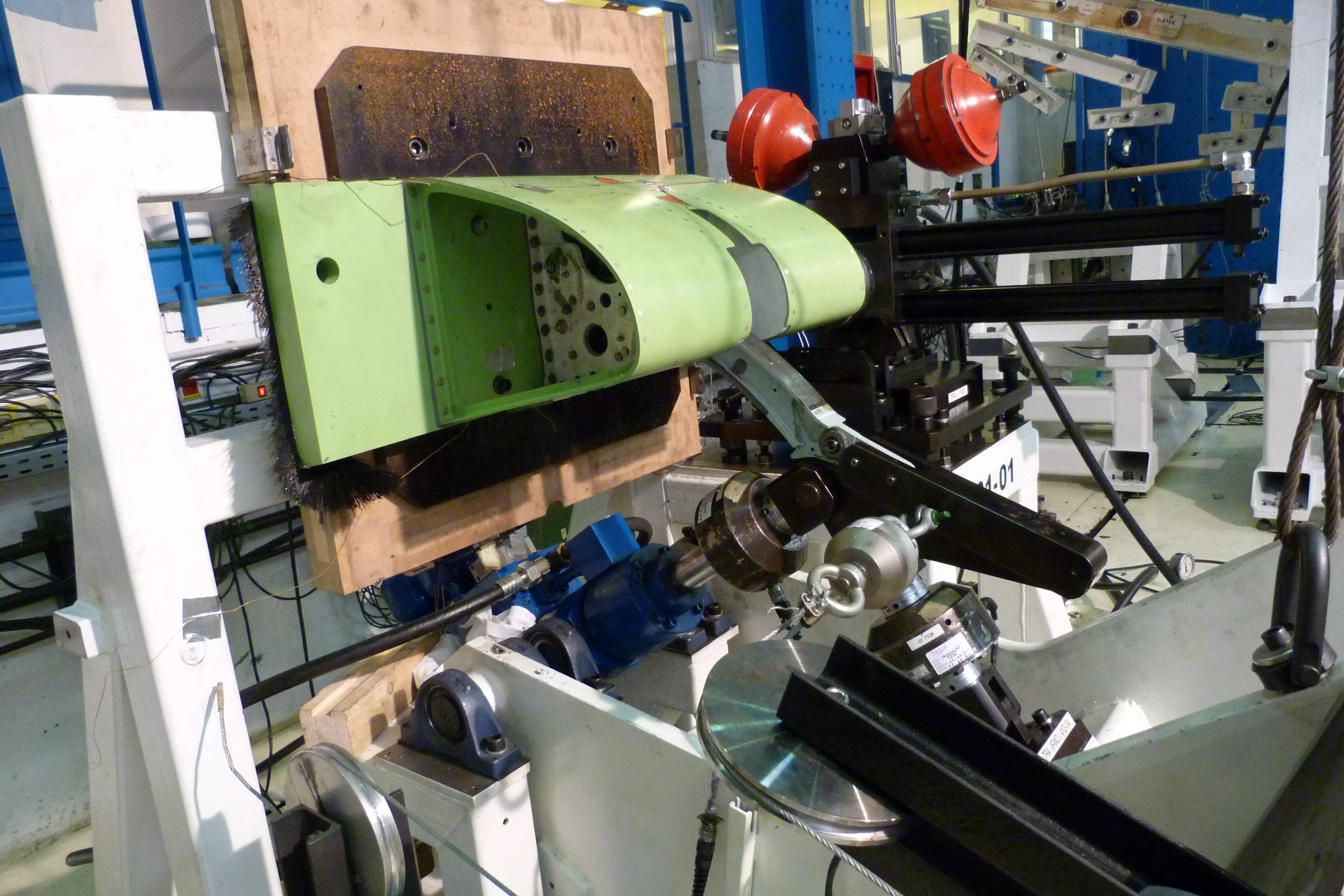

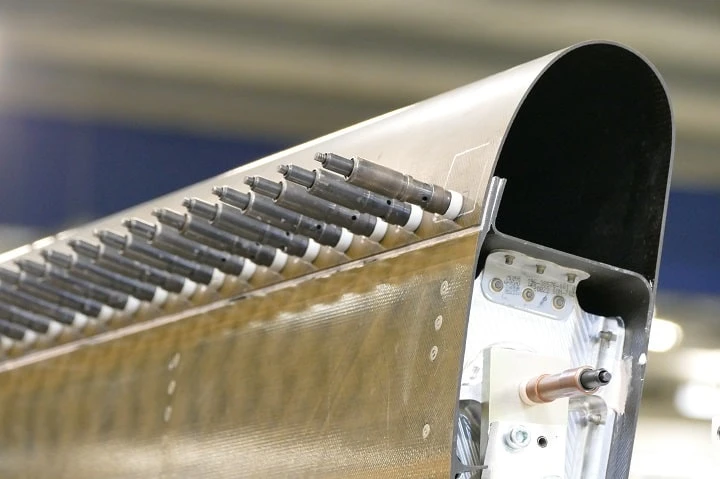

We have developed a robust Rain Erosion Test Bench delivering OEM & Tier1s in aero structures

with accurate results on samples.

The bench test equipment is dedicated to deliver results from rain droplets impacts event. DVI

(detailed visual inspection), IMI (microscopic inspections) and measure of weight loss are

performed for damage characterization.

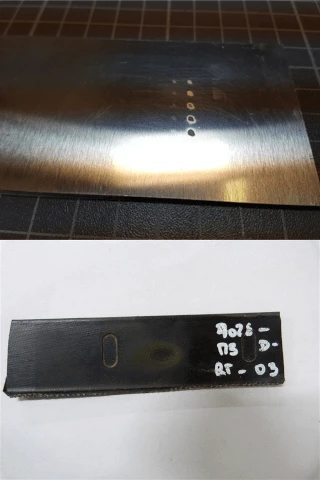

We have developed a dust erosion test bench delivering movables and seal manufacturers with

accurate and reliable results @RT or LT.

The test equipment is intended to provide results simulating impacts of solid microparticles

occurring during flights. The IVC (detailed visual inspection) and IMI (microscopic inspection)

and the measurement of mass loss are performed for damage characterization.

The tribometry bench used at the SONACA Test Center is using an instrumented precision

micro-sander and the ASTM G76-95 standard allowing comparative tests on flat coupons or seal

samples.